Technology has been revolutionizing warehouses for years. Innovations are taking distribution centers into an exciting new era of efficiency. Inventory management used to require lots of slow manual processes. Now, warehouses harness modern systems and Internet of things (IoT) devices to gain new command of operations. This transition is speeding up order fulfillment while eliminating waste. With online shopping exploding, warehouses need major tech disruptions to keep pace with surging volumes.

Why Warehouses Need to Change

Warehouses serve as the beating heart of retail supply chains. They’re responsible for accurately processing and dispatching stock to fill purchase orders. But maximizing warehouse productivity has always presented major challenges. Facility sizes can span more than a million square feet. Tracking inventory by hand resulted in frequent errors. Inventory counts have often been inaccurate, making it harder to pinpoint locations. Without real-time visibility, bottlenecks crippled output capacity for orders. Labor also accounted for up to 70% of warehouse expenses. All these factors lowered accuracy and speed while at the same time driving up costs. Modern customers expect faster deliveries with more transparency. The only way warehouses can meet these demands is by digitally transforming systems and processes.

The Promise of New Technologies

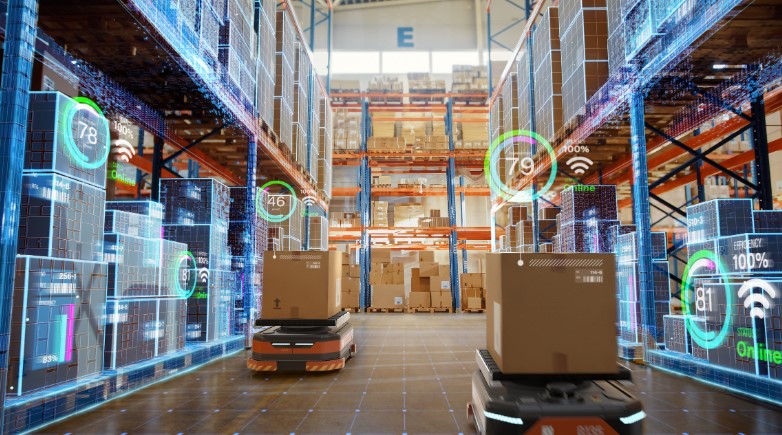

Emerging warehouse management systems are unlocking game-changing analytical potential. Internet of things sensors now connect infrastructure and inventory through digital networks. This enables around-the-clock monitoring across warehouse ecosystems. Software aggregates billions of data points from IoT networks. Advanced analytics convert raw sensor readings into optimized decisions and actions. Artificial intelligence then uses prescriptive algorithms to guide employees and machinery toward maximum efficiency. These capabilities combine to boost accuracy, order turnarounds and labor productivity.

Transitioning Physical Infrastructure

New-age tech stacks need appropriate physical conditions to unlock potential. Lighting systems now use smart LED fixtures with embedded sensors. This allows remote control over color temperature and luminance levels per zone. Programmatic control creates optimal visibility of working conditions. Industrial ethernet now serves as warehouse connectivity backbone. It provides the high speed, low latency data transfers needed to coordinate connected resources. Battery-powered automated guided vehicles offer nimble mobility to shuttle inventory totes between locations. Their autonomous navigation relies on lidar and natural feature tracking to safely maneuver dynamic environments. This prevents downtime from manually changing layouts.

Leveraging the Cloud

Warehouses gain tremendous advantages by moving systems to the cloud. Cloud-based warehouse management software centralizes control in an easy-to-access portal. This enables coordinating operations across the facility from any location. The cloud also streamlines deploying software updates, so technology stays up to date. Scalable infrastructure manages fluctuating data flows to avoid overload. Leveraging robust cloud networks protects operations from local hardware failures. Most importantly, the cloud unlocks advanced analytics through virtually unlimited computing capacity. This allows the development of sophisticated machine learning algorithms to guide automation and complex decision making.

Real-Time Inventory Tracking and Management

IoT for inventory management has revolutionized how warehouses track and control their stock. According to the folk at Blues IoT, IoT implementations provide total inventory transparency through real-time location systems. RFID tags attach to each carton, pallet and product. Wi-Fi and ultra-wideband sensors then track their movement via trilateration calculations. This achieves accurate visibility of inventory items down to the SKU level. Machine learning models categorize items by velocity to optimize placement. Fast-moving products get stored close to shipping zones while slower items move down back. This increases picking and packing efficiency. Edge computing accelerates this by processing data locally before sending analytics. Prescriptive analytics can even forecast inventory needs and trigger replenishments. This allows dynamic alignment with fluctuating demands.

Automating Critical Warehouse Processes

Automatic guided vehicles now handle material transports traditionally performed by forklifts. This automates repetitive low-value tasks to increase throughput capacity. Autonomous mobile robots integrate with warehouse execution systems to map optimized routes between destinations. Computer vision systems streamline processes like order picking that relied on error-prone human selection. Robots can identify items with ultra-high accuracy to fill orders systematically. Standard operating procedures morph into dynamic decision making with automation. Software prescribes actions aligned to broader warehouse needs. As conditions change, prescriptive analytics re-calibrate equipment behavior toward better overall outcomes.

The Lasting Impact of Warehouse Digitization

The next-generation warehouse is emerging as a hyper-connected environment. IoT implementations unite infrastructure, inventory, machinery and staff into a cohesive digital ecosystem. This convergence enables orchestrating operations with cloud-based intelligence. Warehouse optimization now involves harnessing sensor data streams via machine learning to prescribe executable decisions. When insight guides activities across devices and workflows, it unlocks speed, accuracy and savings. Companies that modernize gain immediate advantages, while laggards lose out to customer churn. The warehouse landscape will soon stratify between cutting edge facilities powered by technology integration and outdated ones relying on antiquated manual approaches. Organizations must either board the automation express or risk getting left behind as the industry trains toward a smarter future.

The Human Element

While technology drives warehouse innovation, human insight remains vital. Workers monitor automation to ensure smooth flows and sound early warnings of anomalies. Staff also handle delicate tasks like assessing product damages where mechanical hands may falter. People further excel at judgement calls for exception scenarios outside algorithm parameters. Blending augmented staff with advanced software creates an optimized balance between human oversight and automation efficiency. Allowing personnel to focus less on routine activities also supports better customer service. A happy workforce is crucial for attracting and keeping good employees, especially as distribution methods evolve. The most future-ready warehouses will combine refreshed technology stacks with empowered, vigilant teams.

Conclusion

From sensors to algorithms to autonomous vehicles, innovation is guiding warehouse optimization. Internet of things connectivity provides real-time inventory transparency to optimize planning. Advanced analytics convert data into intelligent decisions while automation handles critical workflows. As technology transforms physical processes, it makes achieving peak warehouse performance simple and repeatable. Companies now have a straightforward path to keep pace with customer expectations through data-driven distribution. The era of the modern warehouse has arrived to usher in fulfillment strategies unmatched in responsiveness and efficiency.

Alternative News

Alternative News